Documentation

combat ready

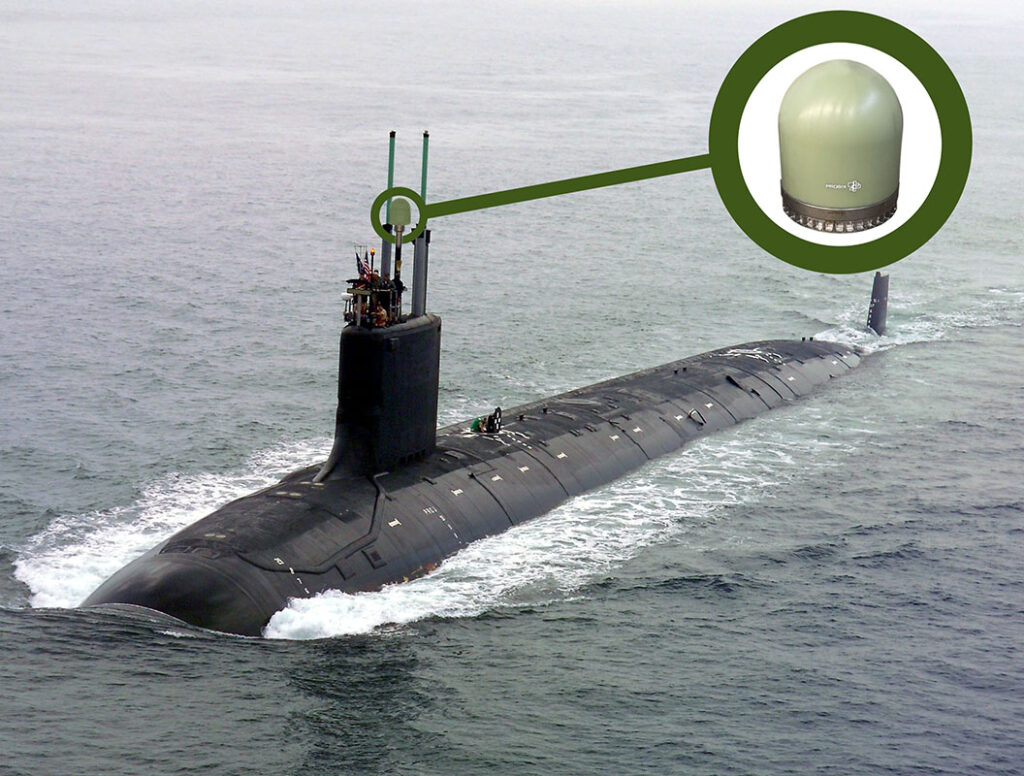

Submarine Radome

DESIGN, QUALIFICATION AND SERIAL MANUFACTURING OF RADOMES UP TO Ka BAND FOR MULTIPLE APPLICATIONS

With our deep knowledge of radio frequency design using composite materials, combined with experience in structural components under massive hydraulic pressures and mechanical expertise in waterproof fixings, we adapt and design the radome to enhance the specific performance of your communication or sensor system. We custom build our radomes for each particular submarine system.

We design, manufacture, test and qualify a range of rugged marine radomes for military use.

Our products are Hydrostatically pressure tested up to 70 Bar, have high frequency transparency with ultra-low RF losses and are fitted with a robust high pressure sealing system guaranteeing lifetime water tightness between submarine and radome.

Our design aims to deliver a high-quality solution for a submarine-carried broadband RF communications and RESM sensor. The radomes main design objectives were to provide top-notch RF performance and create a product that aligns with or surpasses the technology standards employed in marine submarines.

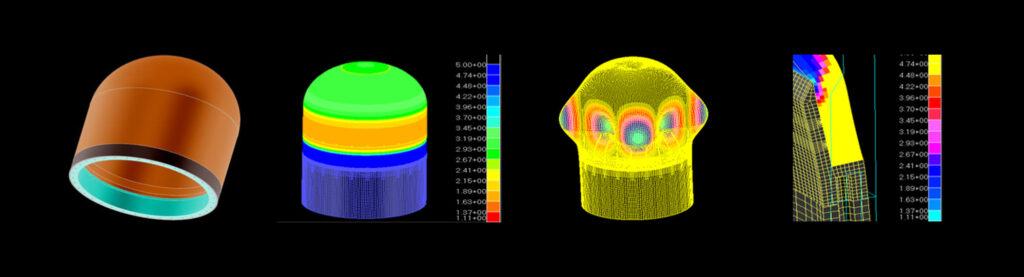

- Multilayer, multimaterial Design,

- Improving frequency bandwidth

- Special impedance matching

- From S to Ka (2-40 GHz) bands SATCOM applications

- Minimal radio frequency (RF) attenuation path

- Ultra high-pressure ruggedness

- Structuraly tough yet lightweight

- High reliability & high performance

- Hydrostatic pressure tank tested at 70 bar

This innovative design can house all sensors in a single uniquely engineered radome to minimize the submarine’s stealth signature. The design can be adapted to any mast hoisting system. It incorporates advanced composite materials, a custom reinforcement design, low-dielectric composites suitable for wide-band RF usage with superior mechanical performance, all produced using a specialized process based on pre-impregnated materials.

Multilayer Design, improving frequency bandwidth Special impedance matching Ultra high pressure ruggednessThe extended large angle analyzer covers a spherical analysis surface with 2000 mm internal radius according to an angular aperture of 113º in the horizontal plane and 92,4º in the vertical plane of the sample.